Unknown Facts About Plastic Injection Molding

Table of ContentsPlastic Injection Molding Fundamentals ExplainedThe Best Guide To Plastic Injection MoldingThe smart Trick of Plastic Injection Molding That Nobody is Talking AboutThe 8-Second Trick For Plastic Injection Molding

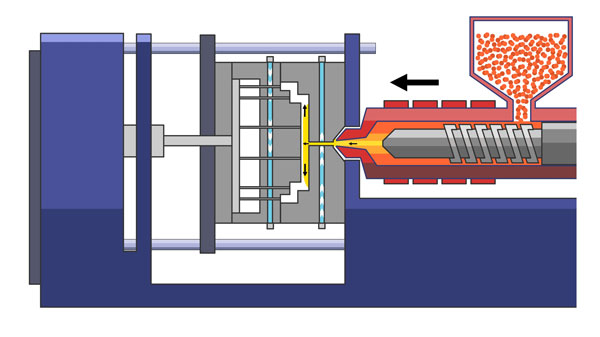

The sequence of events throughout the injection mould of a plastic part is called the shot moulding cycle. The cycle starts when the mould closes, adhered to by the injection of the polymer into the mould dental caries. Once the cavity is filled up, a holding stress is maintained to make up for product shrinkage.

This triggers the screw to retract as the next shot is prepared. When the component is completely amazing, the mould opens and also the component is ejected.: 13 Scientific versus conventional moulding [modify] Commonly, the injection part of the moulding process was done at one continuous stress to load and pack the tooth cavity.

Once the tooth cavity is 98% full, the maker switches over from velocity control to pressure control, where the cavity is "packed out" at a constant pressure, where sufficient velocity to reach desired pressures is required. This lets employees control part measurements to within thousandths of an inch or far better. Various kinds of injection moulding processes [edit] Most injection moulding procedures are covered by the traditional process description over, there are a number of crucial moulding variations including, but not restricted to: An even more extensive list of shot moulding processes may be located right here: Process troubleshooting [ edit] Like all industrial procedures, injection molding can produce flawed components, even in toys.

The Best Strategy To Use For Plastic Injection Molding

Trials are frequently executed before full manufacturing runs in an initiative to predict problems and also determine the proper requirements to make use of in the shot process.: 180 When filling a new or strange mould for the very first time, where shot size for that mould is unidentified, a technician/tool setter might execute a dry run before a full production run. plastic injection molding.

Once they accomplish this, they use a percentage of holding pressure as well as rise holding time till gate freeze off (solidification time) has actually happened. Entrance scorn time can be established by increasing the hold time, and afterwards weighing the part. plastic injection molding. When the weight of the part does not change, eviction has frozen and also say goodbye to material is injected into the part.

, really dangerous if the component is being made use of for a security critical application as the material has really little strength when peeled as the materials can not bond. Excess material in slim layer going beyond normal component geometry Mould is over stuffed or parting line on the tool is damaged, also much shot speed/material injected, clamping pressure also low.

The smart Trick of Plastic Injection Molding That Nobody is Talking About

Loading also quickly, not permitting the sides of the component to establish. Likewise mould might run out enrollment (when the 2 fifty percents don't centre correctly and part walls are not the same thickness). The provided details is the typical understanding, Modification: The Lack of pack (not holding) stress (pack stress is utilized to load out although is the part throughout the holding time).

To put it simply, as the part reduces the the original source material separated from itself as there was not adequate resin in the dental caries. The space could take place at any type of location or the part is not restricted by the thickness yet by the material flow and also thermal conductivity, however it is most likely to take place at thicker areas like ribs or employers.

Knit line/ Blend line/ Transfer line Discoloured line where 2 circulation fronts satisfy Mould or worldly temperature levels set as well low (the material is cool when they satisfy, so they don't bond). Time for shift between shot and transfer (to packing and also holding) is prematurely. Twisting Altered part Air conditioning is as well short, product is too warm, absence of cooling around the device, inaccurate water temperature levels (the parts bow inwards towards the warm side of the device) Uneven diminishing in between areas of the component.

Plastic Injection Molding - An Overview

125 inch wall surface density is +/- 0. The power needed for this procedure of shot moulding depends on several points and also differs in between products utilized. Below is a table from page 243 of the exact same recommendation as previously mentioned that best illustrates the characteristics relevant to the power required for the most generally made use of products.

In addition to installing evaluation systems on automatic devices, multiple-axis robotics can get rid of parts from the mould and position them for more procedures. Certain instances consist of eliminating of components from the mould quickly after the components are produced, as well as using maker vision systems. A robot grips the part after the ejector pins have actually been prolonged to free the component from the mould.

However why is injection molding maker manufacturing so reliable? And exactly how does it function? To learn, let's explore the subject and answer all of the vital visit our website questions, including what it is, the procedure behind it, its major benefits, as well as just how to select the right provider. What is Shot Molding? is the process of utilizing plastic to manufacture a large range of components and items.

The shot molding device makes use of customized mold and mildews to fill them out according to requirements, creating the same copies that can be personalized in a variety of methods. What's even more, injection molding is an extremely functional process, permitting for a broad range of various materials and coatings, which makes it a popular option in plenty of industries with totally different goals as well as needs.